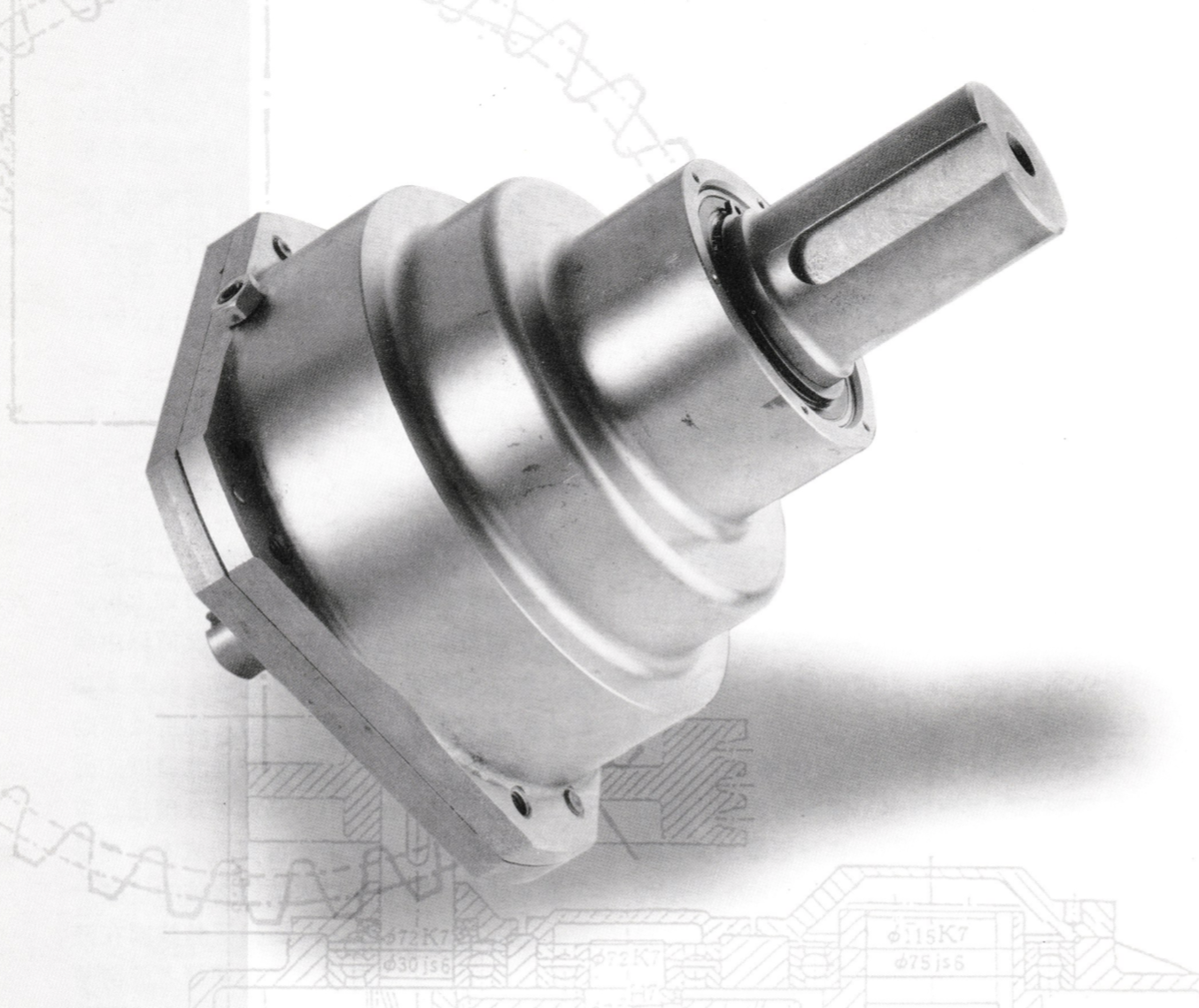

Industry-leading gear technology since 1993

ZY Gearbox: the world’s highest transmission efficiency

With more than 14 granted patents, including patents in US, Europe, Japan, Australia, and China, the ZY gearbox achieves the world’s highest transmission efficiency—as high as 98.6%.

Our mature product, the ZY Gearbox Reducer for general industrial use, is fully developed, tested, and in commercial use. We welcome licensing and technology collaborations, please contact us.

We are constantly innovating in new sectors, including electrical vehicles, aviation, and robotics.

Superior Performance

Transmission efficiency

ZY Gearbox has a transmission efficiency of 0.986 at a transmission ratio of 124— this is the highest transmission efficiency for any gear product. The transmission efficiency has been confirmed in test reports by authoritative institutions including University of the German Federal Armed Forces.

Torque Power

ZY Gearbox has reached torque power of 3000NM/6000NM under a 30-45 kg weight level, which is the highest for any gear product at this weight level. Public comparative testing against state-of-the-art competitor products has been demonstrated. Competitor’s advanced gear products can only reach 1200NM/2000NM under the same weight level.

Precision

At single-stage reduction, ZY Gearbox has a transmission ratio of 2000, generating reverse and precise transmission with sub-arc second precision (U.S. patent pending).

Sustainability: longer service lifetime without toxic heat treatment

With tooth surface hardness of HB250-290, ZY Gearbox achieves a service lifetime of 2×10^10 stress cycles, without applying toxic heat treatment to the gear surface.

Excellence— at lower costs

Compared to other advanced gear products, ZY Gearbox offers reduced pricing for superior performance. Reduction in price is achieved by numerous factors, including reduced number of components, elimination of heat treatment, and replacement of high-grade alloy steel with cast iron while maintaining high performance. For the same magnitude of torque, ZY gearboxes weigh only 1/3 to 1/2 of its peer products, saving up to 60% of resources in producing gear-related devices.